Efficiency

A constant performance capacity and response its tasks.

Each

system

has

been

planned

by

professionals

with

quality

and

efficiency

research

in

order

to

give

prestige

to

their

job.

The

marangoni

dirt

separetor

keeps

this

high

quality

unchan-

ged even during the system operations.

Throughout

the

system

construction

phase,

it

is

possible

to

find

inside

of

it

some

impurities

created

by

the

same

proces-

ses

for

its

creation

(sands

particles,

welding

residuals,

thread

chippings,

metal

flakes,

hemp,

oils

and

process

lubricants,

plastic

fragments;

all

those

elements

who

are

commonly

called

mire).

These

impurities

are

put

into

circulation

when

the

system

is

turned

on

and

that

can

deposited

in

very

sensi-

tive

points.

These

impurities

could

cause

important

instru-

ments

malfunctioning;

block

the

system

by

reducing

the

flow;

create

seizing

and

other

events

that

wold

require

external

assistance, which may slow the product efficiency.

The

dirt

separetor

is

an

active

mechanical

component

of

the

system.

The

Marangoni

Fluid

Technology

stainless

steel

AISI

304

L

system,

compared

to

the

carbon

steel

system

already

available

on

the

market,

defines

clear

and

notable

advantages, among them:

-Inalterability

of

the

component

with

a

constant

performance

throughout time;

-Lacks

of

corrosion

by

maintaining

specific

designs

and

hydraulic flow;

-”Component aesthetic”.

Marangoni

Fluisìd

Technology

is

assisting

professionals

in

order

to

maintain

thei

job

efficient.

Research

materials

accu-

rate

production

processes,

professional

welding

in

TIG

with

qualified

staff

and

constant

innovation

of

the

products

are

the

components

of

our

job

that

aims

to

satisfy

the

always

increa-

sing clients demand.

-

The

dirt

separator

is

completely

stainless

steel

made

AISI

304

L

,

It

is

suitable

to

fluids

transmissions

used

in

thermal

and

conditioning

circuits

(with

every

glycol

percenta-

ge) etc.

The

hydraulic

conformation

of

the

component

and

the

filter

mesh

specific

structures

minimize

the

load

losses.

The

inbound

hydraulic

flux

provides

a

constant

filter

mesh

cleaning

and

the

witheld

material

is

cumulated

in

the

decan-

tation area where it deposits.

The

material

separation

is

obtained

by

using

the

material

specific

weight,

the

flux

speed

reduction

and

the

induced

centrifugal effect.

- Dirt separator with magnet

The

Marangoni

dirt

separator

with

magnets

series

offers

a

powerful

magnetic

structure

that

can

catch

the

numerous

sensitive

particles

during

the

decanting

phase

and

also

directly from the transiting fluid.

The

particles

are

withheld

until

the

periodic

cleaning

in

order

to avoid a return of the cycle.

-The

flanged

Marangoni

dirt

separator

is

composed

by

light

alloy

made

movable

flanges

which

have

been

studied

to

be

directed

according

to

the

fix

flanges

which

are

already

present

in

the

piping

and

in

the

system

elements.

Moreover,

this

choice

involves

a

remarkable

weight

reduction

for

the

dirt separator, which makes it easier to handle it.

The

components

installation

and

fixing

are

then

facilitated

keeping unchanged the efficiency level.

Marangoni dirt separator shows particularities that make it a unique component of high value and prestige:

Marangoni dirt separator

DIRT DEPOSIT

MAGNET ELEMENT

METALLIC KNIT

LABYRINTH

FREE FLANGES

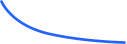

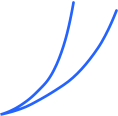

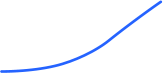

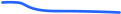

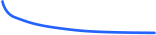

m3/h

m3/h

Cleaning

The periodic cleaning is possible also when the system is

working. To do so, it is necessary shutting the dirt separator

upstream and downstream interceptive valves.

Continuing with the magnet removal and then opening the

ball valve to let impuritiesfalling out.

On demand

- Tailored dirt separators

- Dirt separators with movable stainless-steel made 304 L flanges

- Dirt separators stainless-steel made AISI 316

- Fixtures for big dimensions dirt separators

MAGNET

EXTRACTION

Fluid dynamic characteristics

Separation particles ability

Suggested installation

Boiler

Radiator

Conditioner

Chiller

Load losses

Scopes

Techinical data

THREADED

FLANGED

THREADED

FLANGED

THREADED

FLANGED

Values referred water passage at 70 and with clean filter.

Temperature exercising fiel: -10° ÷ 120°C

Magnetic dirt separator variation load loss compared to the standard or equal models is negligibles.

Model

IN - OUT

Model

IN - OUT

Width

Height

Wheelbase

Widht

Height

Wheelbase

DN 50

DN 65

DN 80

DN 100

DN 125

DN 150

DN 200

DN 50

DN 65

DN 80

DN 100

DN 125

DN 150

DN 200